Once valuable items packaged with EPS (polystyrene) delivered on the end consumers, used EPS becomes a waste that occupies very quickly in a waste skip bins. Hundreds and thousands of tons of waste EPS is currently sent to landfill in Australia rather than recycled.

It is best known that the volume to weight ratio of the EPS is unfavourable for economic transportation after use. Because polystyrene boxes and packaging take up a lot of space in skip bins, running costs are very high for collecting or disposal by trucks. Alternative packaging materials are not rewarding as polystyrene is the best packaging material for many commercial and industrial uses.

Despite of the difficulties of EPS recycling, we are continuously helping to improve EPS recycling rates in Australia. In 2011, less than 10 per cent of EPS was recycled, being one of the most poorly recycled plastics in NSW. It is estimated that 12,000 tonnes of EPS is disposed of to landfill each year, taking up 240,000 m3 of landfill space. Currently, many councils and environmental services providers take part in EPS recycling. It is worth noted that communities and individuals also accord with EPS recycling initiatives in a number of occasions.

- Waste EPS must be segregated from other materials before it is recycled. Ideally the EPS should be separated before it enters the waste stream to avoid contamination.

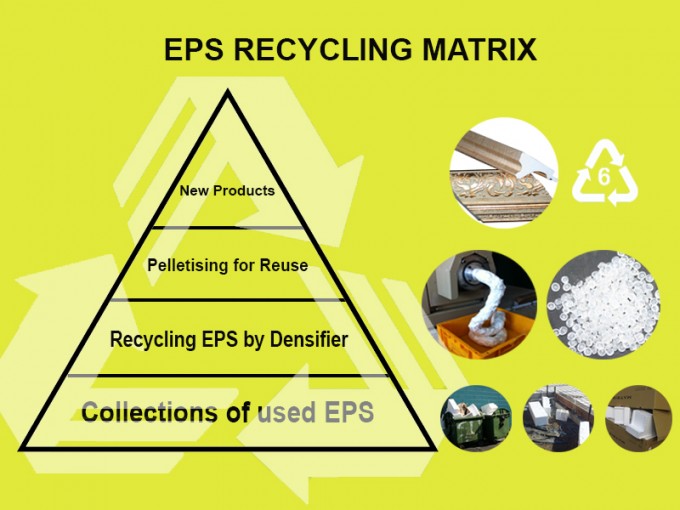

- The collected EPS can be processed by numerous types of compacting machines. However, as shipping cost is a major component of sustainability of increasing recycling rate, volume reduction ratio should be considered for reducing transport cost(both domestically and internationally). When loose foams or scraps are densified by our machine (EPS densifier), it becomes a valuable resources. It is a basic idea for recycling industry as “One man’s trash is another man’s treasure.” So, we do not want to precious resources in landfill.

Densifying EPS: answers for EPS recycling

The EPS densifiers essentially reduce its volumes up to 90% to form a dense block of material. The block can be stored and stacked on pallet then shipped to our facilities. Densified blocks are 100% recyclable as it turns into new products such as cloth hanger and construction materials. High volume reduction ratio also means effectiveness of working hours. It is faster than hydraulic or cold compaction.

What benefits of EPS recycling contribute to sustainable environment?

- Economic perspective: Recycling polystyrene can mean a reduction the frequency and cost of garbage disposal for businesses. Also, recycled polystyrene can be manufactured in to a wide range of products, reducing the demand for virgin products. It is more energy efficient to make products from recycled materials.

- Social and environmental perspective: social and environmental benefits from EPS recycling are intangible but increasingly important because social and environmental effects become an imperative factor for sustainability. Reducing space in kerbside bins and landfill space is the predominant benefit of all advantages.